|

Infinity Truss & Stage Co., Limited

China Steel Stage Light Ring Lock Scaffolding Structure(Real Factory in China) manufacturer |

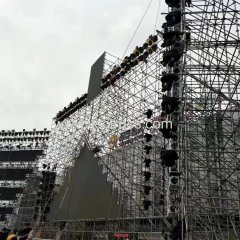

Steel Stage Light Ring Lock Scaffolding Structure(Real Factory in China)

| Price: | 26700.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal,Money Gram |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

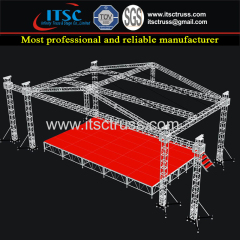

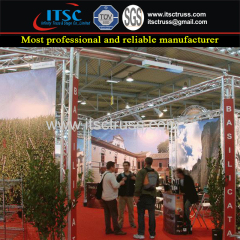

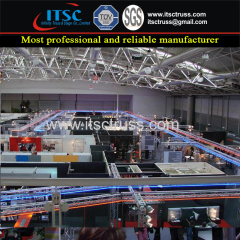

Truss Rigging for stage lighting scaffolding, Various steel lighting scaffolding manufacture, Aluminum lighting scaffolding supplier in China.

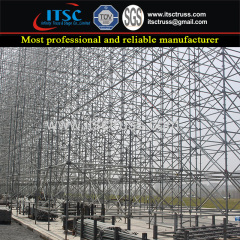

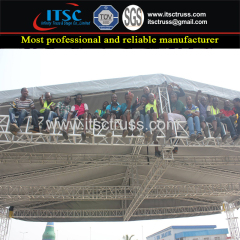

This Ringlock scaffolding truss rigging has the characteristics of high loading capacity and high stability, and it is widely used mainly for high rise building construction. Scaffolding tower is a imple structure with ringlock rosette ,ringlock standard and ringlock.

| Ringlock scaffolding steel tube | Diameter 48.3mm, Thickness: 2.75mm/3.0mm/3.2mm |

| Ringlock scaffolding steel grade | Q235,Q345 Surface:Hot Dip Gal., Electro Gal., Painting |

| Ringlock scaffolding components | Standard, Ledger, Brace, Metal Plank, Ladder, Base jack, Rosette, base colla |

| Ringlock scaffolding rosette | Q235,10mm thickness |

| Standard with spigot, ledger and brace with forged connect point | |

Brief diagram

| Pipes | Sizes |

Ringlock scaffolding Standard / pillars 48*2.5mm - 48*3.25mm Q235 | 0.5m pillar 2 Rings |

| 1.0m pillar 2 Rings | |

| 1.5m pillar 2 Rings | |

| 2.0m pillar 2 Rings | |

| 2.5m pillar 2 Rings | |

| 3.0m pillar 2 Rings | |

Ringlock scaffolding horizontal pipe 48*2.5mm - 48*3.25mm Q235

| 0.6m Ledger |

| 0.9m Ledger | |

| 1.2m Ledger | |

| 1.5m Ledger | |

| 1.8m Ledger | |

| 2.4m Ledger | |

Ringlock scaffolding Diagonal pipe 48*2.5mm - 48*3.25mm Q235

| 60*100mm 1170mm |

| 90*100mm 1334mm | |

| 150*100mm 1776mm | |

| 180*100mm 2028mm | |

| 60*150mm 1632mm | |

| 90*150mm 1752mm | |

| 150*150mm 2160mm | |

| 180*150mm 2322mm | |

| 240*150mm 2802mm | |

| 240*200mm 3091mm |

Heavy loading capacity and stable,

Demountable,easy to assemble and transport

Self-locking, non-rust

because of the Accessories are not easy to be lost and Good stability, widely used in bridge construction

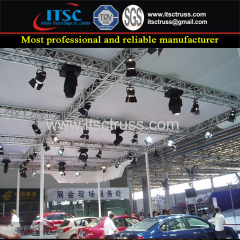

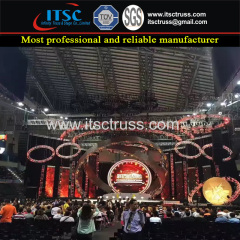

support, hanging speaker, stage background, light frame and other fields.

Our partners

The process of orderng scaffolding.

Negotiating | Specification |

Quantity | |

Price | |

Packing | |

Delivery Time | |

Terms of Payment | |

Claim for Compensation | |

Arbitration | |

Sign a contract | Order goods and stamp |

Transfer payment | Cash, T/T, Western union, Money gram, L/C, ect |

Prepare production | PD study the specification and start to arrange the production, |

Check and Testing | QC checking and testing the quality |

Packing | Generally pack with bubble air or carton according to negotiation |

Step 1 | Material Ready |

Step 2 | Material Cutting |

Step 3 | Board Cutting |

Step 4 | Punching |

Step 5 | Milling |

Step 6 | Welding |

Step7 | Checking |

Step 8 | Testing |

Step 9 | Packing |

By sea: 15-45 days acocording to different countries

It takes 3-5 hours to set up with thespeaker towers

Clean, check and maintain your scaffolding on a regular basis.

Throw away the damaged or deformed scaffolding, spigot pins or couplers.

Make a structural calculation for each construction you build.

Store and transport your scaffolding on proper dolly.

Attach loads in node points.

Check how loads are attached to the speaker towers before lifting.

Mix scaffolding rigging of multiple suppliers in one construction, unless specifically stated by manufacturer.

Exceed the maximum loading of single spans as specified in the loading tables.

Exceed the given structural data of scaffolding.

Drill holes in the tubes.

Use damaged scaffolding.

Attach loads to the scaffoldingdiagonals.

All goods are only factory competitive price guarantee and 100% quality inspection before delivery.

Instant feedback for any inquiry.

Professional designs and welding.

Quality satisfaction guarantee 100% return policy.

Sample or trial order is acceptable, Mixed order support, fast delivery.

Much rich experience in dealing with international trade and declaration with more than 8 years in this line.

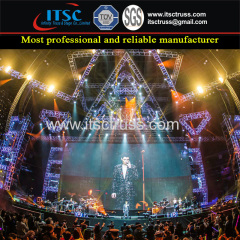

We have been designing and manufacturing event truss and stages many years. Our leading design teams and strict quality control systems ensure each product from ITSC truss is reliable and ideal deals. Our quality products have well met demands of all clients around the world.

With our own factory and product line, ITSC truss can ensure the fastest delivery in the industry. What's more, we have accumulated rich resources in shipping channels, which also promise our fastest delivery time. Our standard cases can be finished within 7days and those custom-made within 8 days.

We are committed to providing the most affordable products for all customers. We have our own factory and massive production line. This ensures that we can procure all materials at much lower price than our competitors.

We promise all products from ITSC truss are the most affordable in the industry.

Choose your most reliable supplier, choose ITSC truss!

In a word, we are one of the most professional and reliable truss and stages suppliers in China. Please come to us!

ITSC truss is a professional supplier and solution provider of exhibition and display system, located in Guangzhou, China.Our factory is near Baiyun AirPort, about thirty minutes drive from Baiyun Airport to factory.

Our products range includes standard and custom made exhibition booth, and we also produce tension fabric fast trade show booth and aluminum truss system and layer.

About trade show services in China, we also can make and sell alumninum truss exhibition booth for your needed booth building services in different exhibition centers in Guangzhou,Shanghai, Beijing, Guangzhou, Shenzhen.

We believe that quality is the life of the factory.

Providing the high-quality products is our company's responsibility.

ITSC trus is willing to co-operate with you and create the future brilliance together. Thank you!

Welcome to Shanghai; Welcome to ITSC truss

All the scaffolding are gavanized and in stock now!

Steel scaffolding for stage lighting fixture and LED screen and sound functions in Concerts Events.

Related Search

Find more related products in following catalogs on Hisupplier.com

Other products from this supplier

-

Layer Truss Scaffolding Stage System for Indoor Concert EventsITSC-LT1414-8mH

-

Pyramid Roofing Trussing System from ChinaITSC-PR303025F

-

Hercules Orbital Exhibition & Dispaly Truss RiggingITSC-TRED002

-

Exhibition Stage Truss Booth KitsITSC-TRED002